Parameter

Product Name : Angle steel roll forming machine with punching

Condition : New

Usage : Building

Production Capacity : 0-20m/min

Voltage : 380V 50Hz 3phases

Power(W) : 4+4KW

Dimension(L*W*H) : 6500*1300*1100mm

Weight : 3.5T

Forming Steps : 9 Steps

Description

Angle steel roll forming machine with punching

If you are interested in my product, contact me at any time! I am waiting for you~

wangy@mec.com.cn

Whats app: 0086-15164015358

zhaoyh@mec.com.cn

Whats app: 0086-18842637815

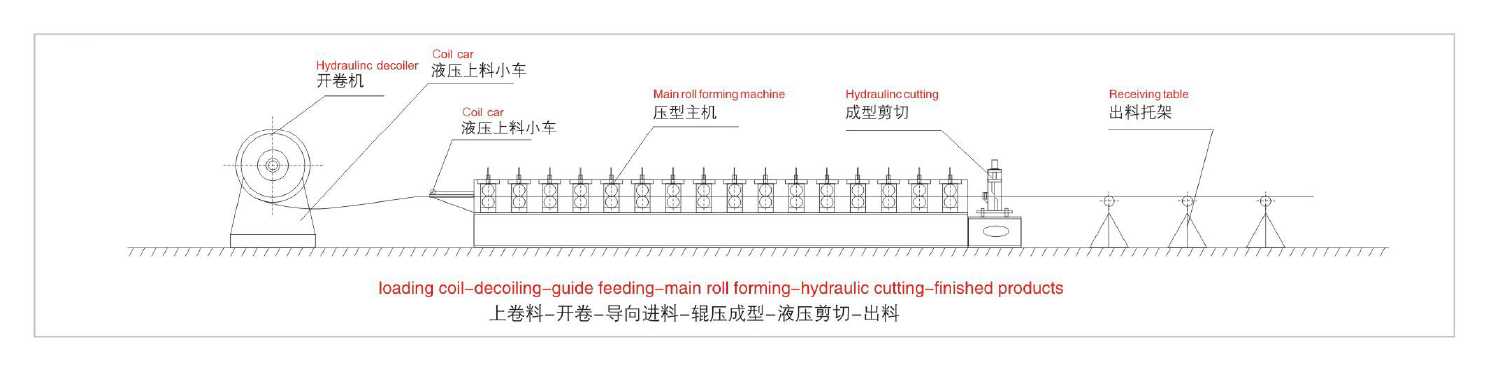

Process flow:

Process detailed:

Machine Parts

Name: Decoiler

Main Features

Inner diameter:350-450mm

Outer diameter:450mm

Coil width:300mm

Capacity:1.5T

Machine Parts

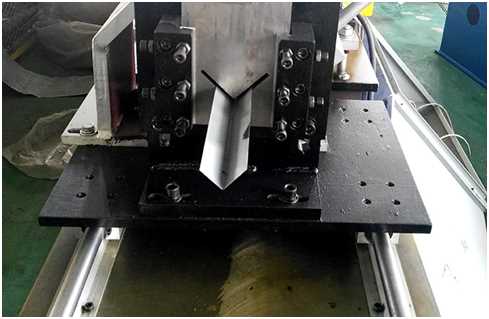

Name: Main roll forming machine

Main Features

Roller station:9 stations

Shaft material:45# steel

Diameter:50mm

Roller material: GCr12

Transport: Gear Driving

Forming Speed: 0-20m/min

Cutting Model: Hydraulic tracking cutting

Length Measurement: counter

Machine Parts

Name: Cutting System

Main Features

Cutting blade: GCr12

Cutting type: Hydraulic tracking cutting

4KW oil pump one set

Machine Parts

Name: Screen( touch screen)

Main Features

PLC control

PLC: Delta

Screen: Delta touch screen

Automatic length and quantity measurement

Control station is used to control product length and quantity, automatically cutting to length and stop when required quantity is achieved.

Error is easy to adjusted.

Two mode interchange' one is fully automatic the other one is semi-automatic

Machine Parts

Name: Reiceiving table

Main Features

The table can be strengthening.

The finished product

Packaging & Delivery

|

Packaging Details:

|

20 Feet Container Standard Packing For roof sheet roll forming machine

Main machine :All rollers will be brushed unti-rusty oil, and packed with waterproof plastic film

Control box: Be packed with thick cardboard, and outer side thick waterproof plastic film.

All parts inside container will be fixed very well which can keep safety and fixed for long

time sea transportation.

|

|

Delivery Time

|

45 Days

|

Our service

Pre-Sale service

- Could provide sample to client

- Help clients design profile optimize base on our engineer suggestion

- Figure out client’s technical confusion

In-Sale service

- We would provide manufacturing progress information per week

- Help you check competitive shipping company and freight

- Would help you purchase raw material for testing machine

After-Sale Service

- Our engineer are available service oversea in warranty period

- Out of warranty period we also provide remote technical support.

Year Established:1994

Business Type:Manufacturer, Trading Company

Management Certifiation: ISO9001:2008 GB/T 19001-2008

Operational Address: World Trade Center, No.25 Tongxing Street, Dalian, China

Verified Supplier

Credit Check