Description

- Place of Origin:Shaanxi, China (Mainland)

- Brand Name:ASS

- Model Number:2360 2750 3150 3350 3505

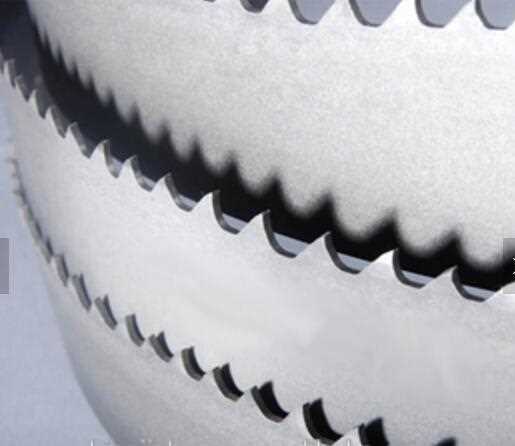

- Blade Material:Alloy Steel

- Finishing:Ti-coated

- Size:5 6 8 10 13 19 20 27 34 41 54 67

Conventional specifications (width X thickness): (27--------41) * (0.9---1.3)

Commonly used teeth, tooth number: 4/6T, 2/3T, 3/4T

Band length: the standard length, also can be customized in length

Band saw common specifications:

27mm:3505mm,3250mm,3620mm,3820mm,3350mm,3150mm,4980mm,3145mm

27mm width: 3505mm, 3250mm, 3620mm, 3820mm, 3350mm, 3150mm, 3145mm, 4980mm

34mm:3820mm,3900mm,4570mm,4680mm,3620mm,3850mm

34mm width: 3820mm, 3900mm, 4570mm, 4680mm, 3620mm, 3850mm

41mm:5450mm,5300mm,6460mm,5470mm,5040mm

41mm width: 5450mm, 5300mm, 5470mm, 5040mm, 6460mm

Product advantage: equal tooth is suitable for cutting various materials. The teeth can reduce the vibration and noise when cutting.

Scope of application: bar 25<F<300mm, profile wall thickness 3-30mm, stainless steel, sawing high hardness, high plasticity material

The combination of high speed steel tooth tip and the quality of material, let the band saw blade become most metal cutting applications are the most cost-effective choice. A variety of product types can ensure that you get the best performance when your application is.

In the new band saw use the correct running program is very important, the band saw blade and prolong the service life of more than 50%. Rolling precision grinding or abrasive band saw blade usually have very sharp teeth, if the tooth tip to gradually grinding to a radius. In the first cutting material is extremely easy to lead to abnormal wear. Similar to the serrated sharpened sharpened pencil: if the pressure is too large, very sharp teeth will immediately break. However, if gradually increasing pressure on the pencil, the pencil core will form a round tip, and can withstand greater pressure, longer duration. In the proper running, forming a band saw blade radius (circle), the sawtooth to prevent premature fragmentation. The product design also plays an important role in preventing premature breaking of the tooth tip.

Saw blade for workshop and foundry, applicable to contour and shape of sawing, applicable to all varieties of steel, solid material continuous sawing and bundles of sawing, suitable for small to medium sized objects. Applies to all production sawing, suitable for all kinds of alloy steel from the low. Containing cobalt alloy band saw blade, saw this type of performance especially in all types of metal continuous sawing, sawtooth with 8% cobalt and 10% molybdenum alloy high speed steel is made. Advantages: cutting speed with respect to the tool hacksaw blade increased 30-100% by sawing time can be reduced by 50%, the productivity higher working life is tool hacksaw blade 10%, increase the cutting precision both one-time operation and continuous operation of sawing sawing work can get better cost effect

Packing

| Selling Units: |

Single item |

| Single package size: |

60X68X38 cm |

| Single gross weight: |

6.5 KG |

| Package Type: |

Carton box |

Year Established:2010

Business Type:Trading Company

Management Certifiation:

Operational Address: 2/F, Bldg. 4, 188 Gaoxin Avenue, High-tech Development Zone, Baoji, Shaanxi, China (Mainland)

Verified Supplier

Credit Check