Parameter

Colors : 6

Description

Reel-to-Reel Flexible Printing Machine

|

Reel-to-Reel Flexible Printing Machine (JLD-800)

|

|

Diameter of unwinding cloth

|

1,200 mm Maximum

|

|

Width of unwinding cloth

|

Max. 800mm

|

|

Printing width

|

Max. 680mm

|

|

Printing length

|

Max. 1,200mm

|

|

Bag length

|

Max. 1,300mm

|

|

Printing speed

|

45-70pcs/min.

|

|

Deviation in length

|

±0.5mm

|

|

Deviation in chromatography

|

±0.5mm

|

|

Thickness of printing plates

|

4-6mm

|

|

Total power

|

31Kw

|

|

Compressed air consumption

|

0.4m3/min.

|

|

Dimensions (L×W×H)

|

16500×2010×1600mm (6 colors)

|

|

Weight

|

6000Kg (6 colors)

|

Main Features:

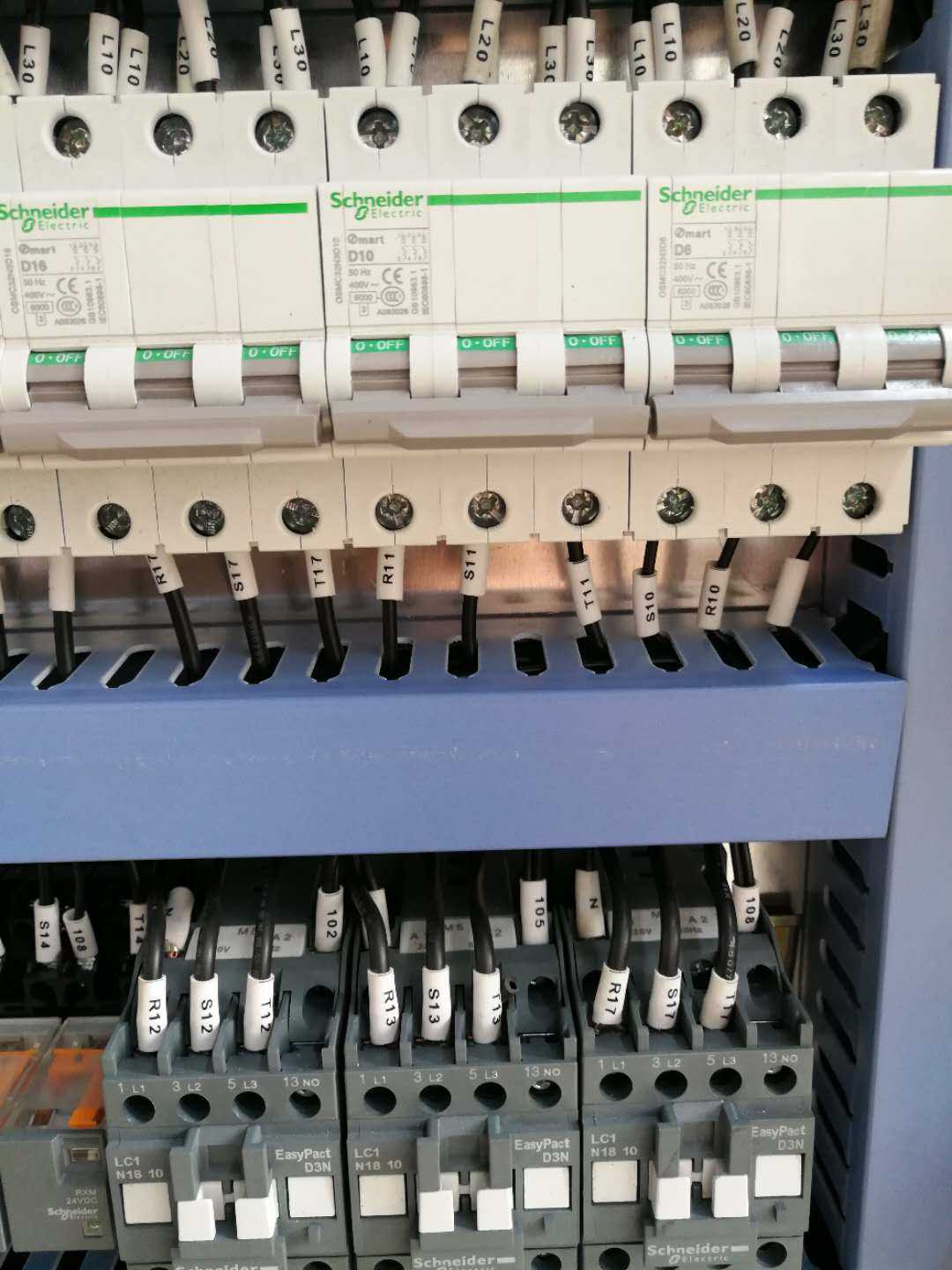

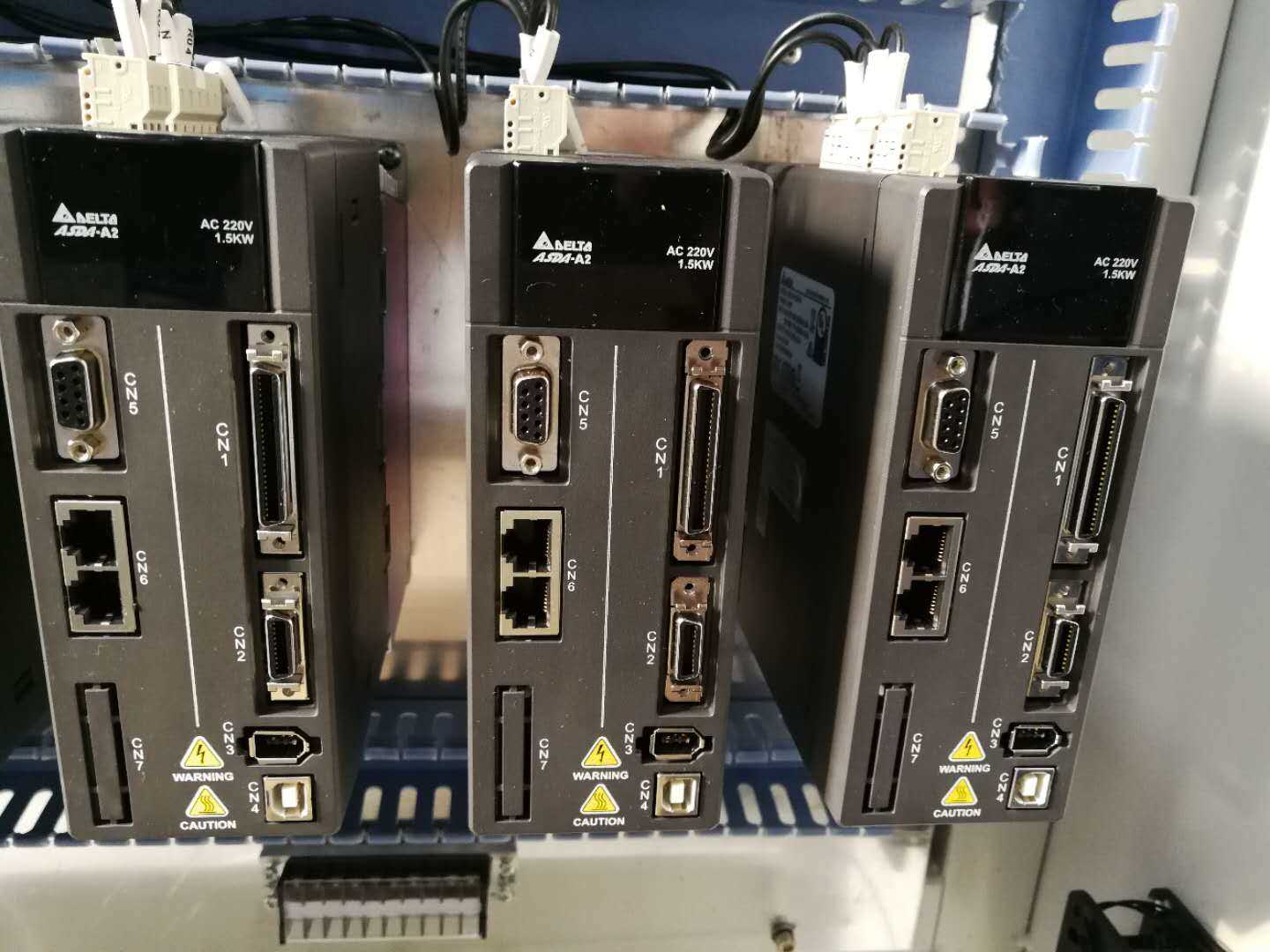

-Electrical parts: Only international famous brands are used for stable performance, less maintenance and saving of spare parts.

-Unwinding part: Pneumatic devices, photoelectricity sensors, frequency converter and dancing rollers are used for stable and precise feeding of fabric from roll.

-Color mark tracking: Photoelectricity is used for more accurate tracking.

-Chromatography: None-stop online chromatography by printing plates roller helps the easier operation and also less waste of fabric.

-Pneumatic ink pump: The pneumatic ink pump is mounted for less need of labor and also even spreading of ink.

-None change of roller: The length of bag is controlled by servo motor that doesn’t need any change of the printing roller. This will save the production costs

-Better drying after printing: The fan circulating oven is mounted for drying at constant temperature.

-Easy & even winding: The winding after printing is controlled by frequency converter, which has the automatic counting and makes even tension of fabric in roll for next bag making.

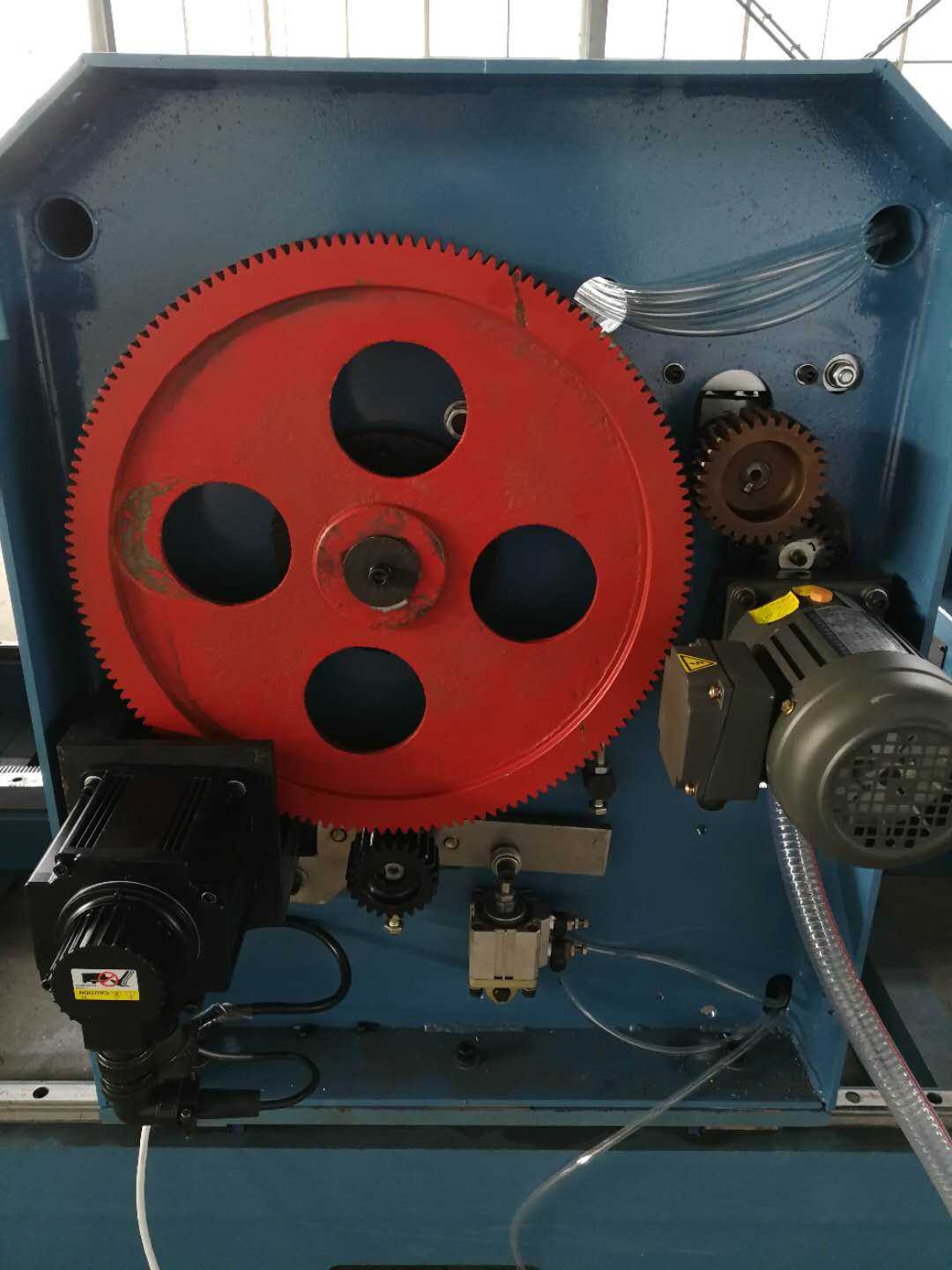

Detailed Images

Lead Time: 30 working days after deposit

Packaging: Pallet and film wrapping

Year Established:

Business Type:Manufacturer, Trading Company

Management Certifiation:

Operational Address: 28/F,World Trade Center,No.25,Tongxing Street,Dalian,China

Verified Supplier

Credit Check